With over 20 years of experience in the medical device manufacturing and hydrophilic coatings industry, Intrface Technolgies has the most comprehensive solutions and process development support for Atmospheric Plasma Treatment for Medical Device Applications.

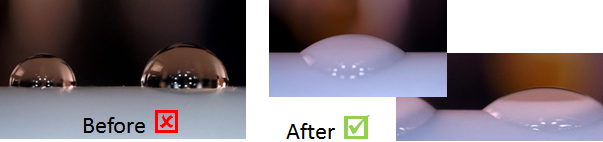

Our atmospheric plasma treatment solutions allow you to free your medical device manufacturing process from dangerous wet chemicals and unreliable abrasion surface preparation methods. Intrface Technologies high speed atmospheric plasma systems offer safe, clean, cost effective solutions for non-contact surface preparation prior to bonding, coating and marking.

One of the main benefits of atmospheric plasma treatment versus vacuum plasma systems is the ability to run in a true in-line continuous flow, single piece or single part manufacturing environment. Many medical device manufacturers are focused in creating single part traceability in their manufacturing process to ensure the highest possible reliability and accountability to regulatory agencies and are moving away from batch vacuum plasma process flows to in-line atmospheric plasma process flows.

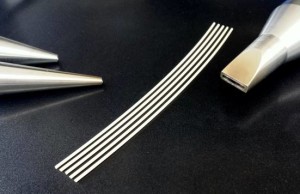

Intrface offers several proprietary in-line non-contact atmospheric plasma sources and chemical plasma technologies designed specifically for the needs of the medical device manufacturing industry. We know how to plasma treat heat sensitive materials and have developed specialized atmospheric plasma sources to plasma treat and handle microcatheters and guidewires for non-contact surface cleaning, activation and modification prior to bonding, coating and printing or marking.

With our expertise in hydrophilic and antimicrobial coatings we have helped our customers improve durability and lubricity performance on catheter coatings and guidewire coatings. PEEK (Polyether ether ketone) and Polyimide are two catheter materials that generally require atmospheric plasma cleaning and activation in order to achieve acceptable bond or coating performance. Intrface Technologies can help you achieve significant savings on your coating costs by eliminating catheter and guidewire primers and tie layers. Utilizing our atmospheric plasma treatment systems, we can help you develop a primer free hydrophilic coating on DEHP free (Di (2-ethylhexyl) phthalate) Polyvinyl Chloride (PVC) catheters for Intermittent Self Catheterisation (ISC).

Whether you are making PTFE, PVP hydrophilic UV cure, PVP hydrophilic heat cure or hyaluronic acid hydrophilic coated catheters or guidewires, Intrface Technology atmospheric plasma systems offer a clean, safe and non-contact method for cleaning, and modifying all catheter substrates and stainless steel and NiTi (Nitinol) guidewires prior to hydrophilic coating. Atmospheric plasma treatment can also improve the durability, cleanliness and performance of intraocular lens introducers (IOL) and coatings used in cataract surgery.

Maximize the durability and minimized the thickness of medical device hydrophilic and antimicrobial coatings by cleaning and activating surfaces of peripherally inserted central catheters (PICC or PIC line), introducers, sheaths, ports or port-a-cath and microcatheters with atmospheric plasma treatment prior to the coating process.

We know atmospheric plasma treatment for medical device manufacturing applications. Intrface Technologies is in a unique position to be able to offer several different types of atmospheric plasma technologies targeted to our expertise in solving cleaning, bonding, coating, functionalization and sterilization challenges.

Related Articles:

- Perez-Martinez, J. A., Pena-Eguiluz, R., Lopez-Callejas, R., Mercado-Cabrera, A., Valencia, R. A., Barocio, S. R., Benitez-Read, J. S., and Pacheco-Sotelo, J. O., ” An RF microplasma facility development for medical applications,” Surf. Coat. Technol. 201, 5684 (2007). Abstract: Microplasmas represent, by their physical nature, a considerable potential for medical applications given their highly accurate action and extremely controllable penetration on the surface of biological tissue. This plasma modality is today a powerful tool in practical applications such as the elimination of necrotic cells or the sterilization of dental cavities. As we start up a research line into this technology, we have constructed a plasma needle capable of producing non thermal plasmas, within a 1 mm radius, produced by a typical 13.56 MHz RF generator. The plasma is developed out of helium and argon. Initial electrical tests show that the plasma needle can operate at comparatively low voltages (peak to peak 100–250 V) and low power consumption. With a view to optimizing the medical applicability of the system, a study of the effects of plasma temperature and power variation at different distances is presented.

- Weltmann, K. D., Brandenburg, R. Von., Woedtke, T., Ehlbeck, J., Foest, R., Stieber, M., and Kindel, E., “Antimicrobial treatment of heat sensitive products by miniaturized atmospheric pressure plasma jets (APPJs),” J. Phys. D: Appl. Phys. 41, 194008 (2008). Abstract: The technological potential of non-thermal plasmas for the antimicrobial treatment of heat sensitive materials is well known. Despite a multitude of scientific activities with considerable progress within the last few years, the realization of industrial plasma-based decontamination or sterilization technology remains a great challenge. This may be due to the fact that an antimicrobial treatment process needs to consider all properties of the product to be treated as well as the requirements of the complete procedure, e.g. a reprocessing cycle of medical instruments. The aim of this work is to demonstrate the applicability of plasma-based processes for the antimicrobial treatment on selected heat sensitive products. The strategy is to use modular, selective and miniaturized plasma sources, which are driven at atmospheric pressure and adaptable to the products to be treated. Antimicrobial treatment of heat sensitive products by miniaturized atmospheric pressure plasma jets (APPJs).

- Chu, P. K., Chen, J. Y., Wang, L. P., and Huang, N., “Plasma-surface modification of biomaterials,” Mater. Sci. Eng. Rep. 36, 143 (2002). Abstract: Plasma-surface modification (PSM) is an effective and economical surface treatment technique for many materials and of growing interests in biomedical engineering. This article reviews the various common plasma techniques and experimental methods as applied to biomedical materials research, such as plasma sputtering and etching, plasma implantation, plasma deposition, plasma polymerization, laser plasma deposition, plasma spraying, and so on. The unique advantage of plasma modification is that the surface properties and biocompatibility can be enhanced selectively while the bulk attributes of the materials remain unchanged. Existing materials can, thus, be used and needs for new classes of materials may be obviated thereby shortening the time to develop novel and better biomedical devices. Recent work has spurred a number of very interesting applications in the biomedical field. This review article concentrates upon the current status of these techniques, new applications, and achievements pertaining to biomedical materials research. Examples described include hard tissue replacements, blood contacting prostheses, ophthalmic devices, and other products.

- Vandencasteele, N., Fairbrother, H., and Reniers, F. A., “Selected Effect of the Ions and the Neutrals in the Plasma Treatment of PTFE Surfaces: An OES-AFM-contact angle and XPS study,” Plasma Process. Polym. 2, 493 (2005). Abstract: Polytetrafluoroethylene (PTFE) surfaces were treated by oxygen and nitrogen species generated either in a remote (filtered) RF plasma or in an ion gun. In the first case, the majority of the species reaching the surface are neutral molecules, whereas in the second case, ions are the reactive agent. In this paper, we show that ions alone do not lead to a significant grafting of new functions on the PTFE surface. The XPS analysis of the treated surface show identical behaviour with oxygen and nitrogen ion treatment, and the evolution of the C1s peak shape suggest a progressive sputtering, leading to defluorination of the surface. The nitrogen plasma treatment lead to a subsequent grafting that is attributed mostly to the “excited neutrals”, but we suggest here that the ions could play a significant role in the activation process of the surface. The exposure of PTFE to an oxygen plasma lead to chemical etching of the surface, different from the physical sputtering induced by the ion treatment, that lead to a super-hydrophobic behavior of the surface attributed to an increase in the surface roughness.

Contact us to find out more about using atmospheric plasma in your medical device application or to receive a complimentary copy of the technical articles utilizing atmospheric plasma above. Please reference the authors and publication number in your email request (copy and paste into your email response).